Biomass Conversion and Biorefinery

The term biomass describes all substances of organic and thus carbon-based origin. This includes all plants and animals living in nature (primary biomass) and the resulting residues (secondary biomass). In a broader sense, the products of a technical conversion or material use of biomass (e.g. paper, slaughterhouse waste, organic household waste fraction) also count as biomass.

A form of "rotting", also known as carbonization, turns biomass into fossil fuel. This is how peat is first produced, which in time turns into lignite and then stone coal. This naturally occurring process of coal formation, however, is too slow in the human sense of time. Huge amounts of coal, which formed naturally over millions of years, have been burned during the last 200 years. The same applies to petroleum, which, in addition to being used as an energy source, is also the precursor for the production of a large variety of base chemicals.

Various processes and technologies have been developed to replace fossil and thus finite raw materials with renewable raw materials. We differentiate:

- Biomass Conversion Processes for the production of biochar or peat substitute.

- Biorefinery Processes for the production of precursors and base chemicals.

Biomass Conversion

Thermochemical Processes

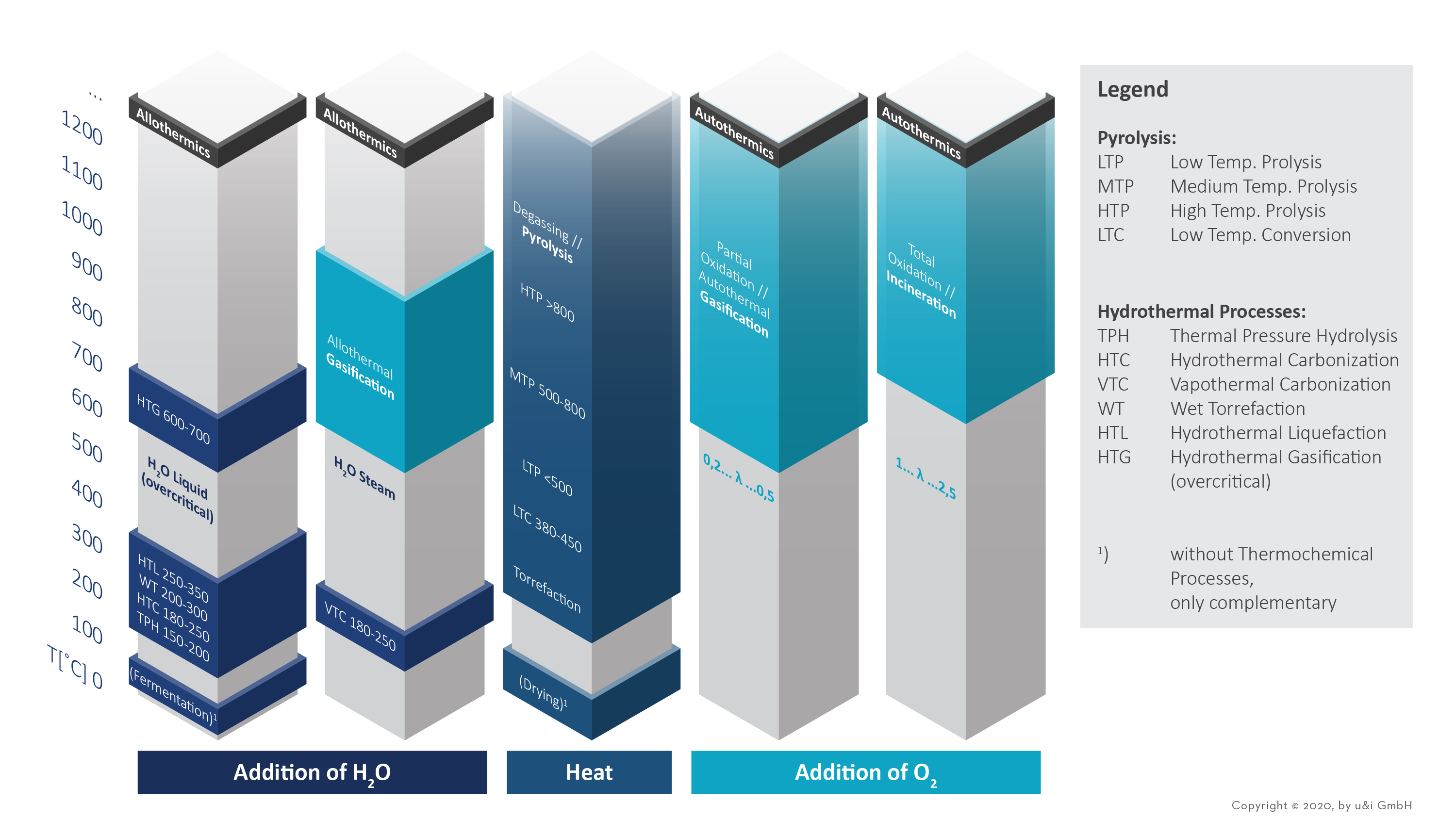

Depending on the respective milieu (presence of water or oxygen) and the temperature range of the process, the products differ. While in classical incineration, all organic material is oxidized, the nature of the remaining organic material changes in the other processes. Almost all of the processes in the figure, which are located to the left of complete combustion, produce solid products (some of which are sludgy but easily dewaterable) that have charcoal-like properties and are referred to as biochar or hydrocharcoal.

In particular, the processes to be highlighted are:

- Gasification

- Pyrolysis

- Hydrothermale Carbonisierung (HTC)

- Vapothermal Carbonization (VTC) and of course the

- Fermentation

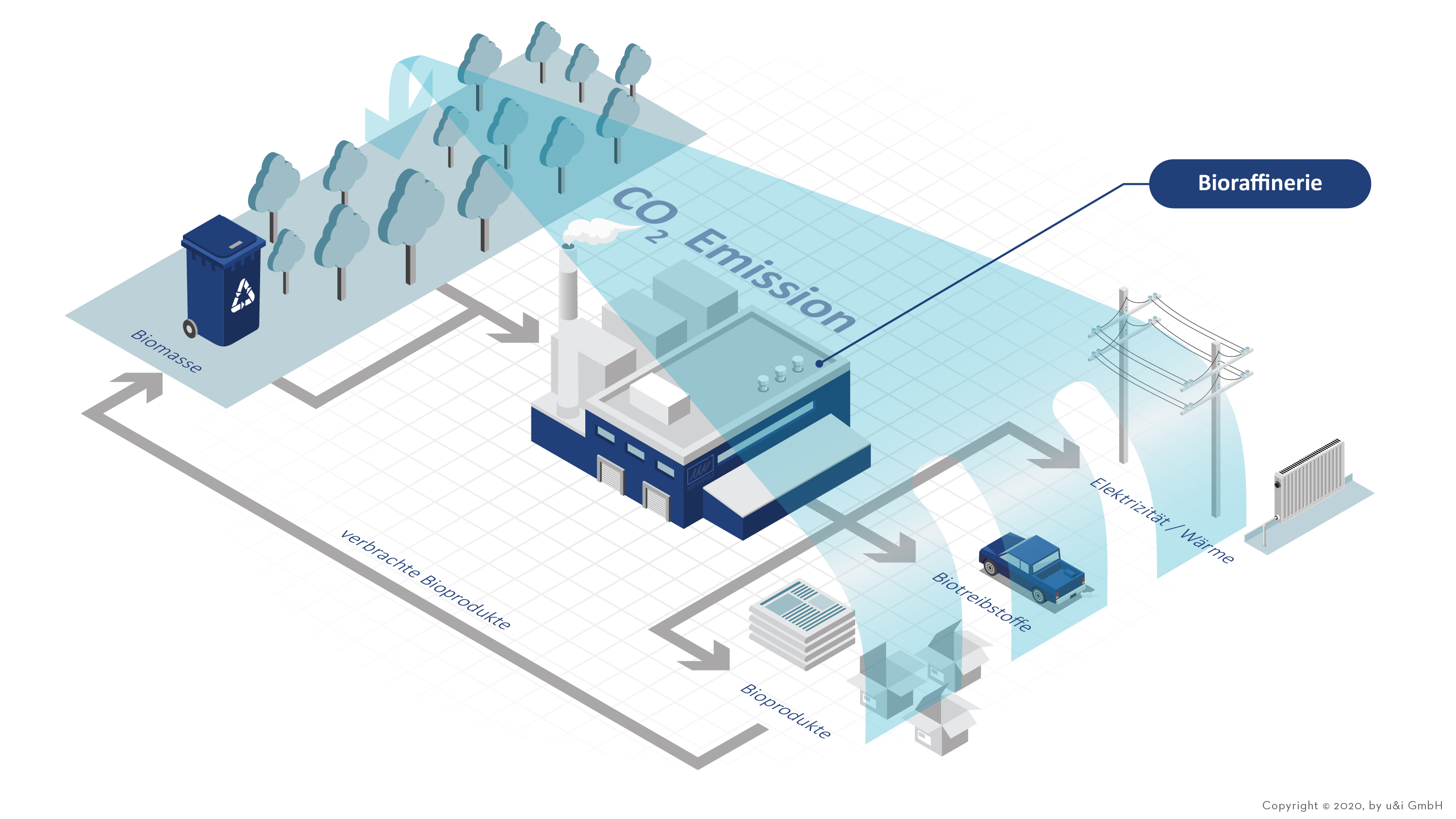

Biorefinery

Both biomass conversion processes and biorefineries are technologies that are gaining importance against the background of the socio-political discussion about sustainability and climate change.

We have many years of experiences in the area of approval planning and the implementation of large-scale projects, we are more than capable of supporting your project. Please feel free to contact us.