Carbon Dioxide

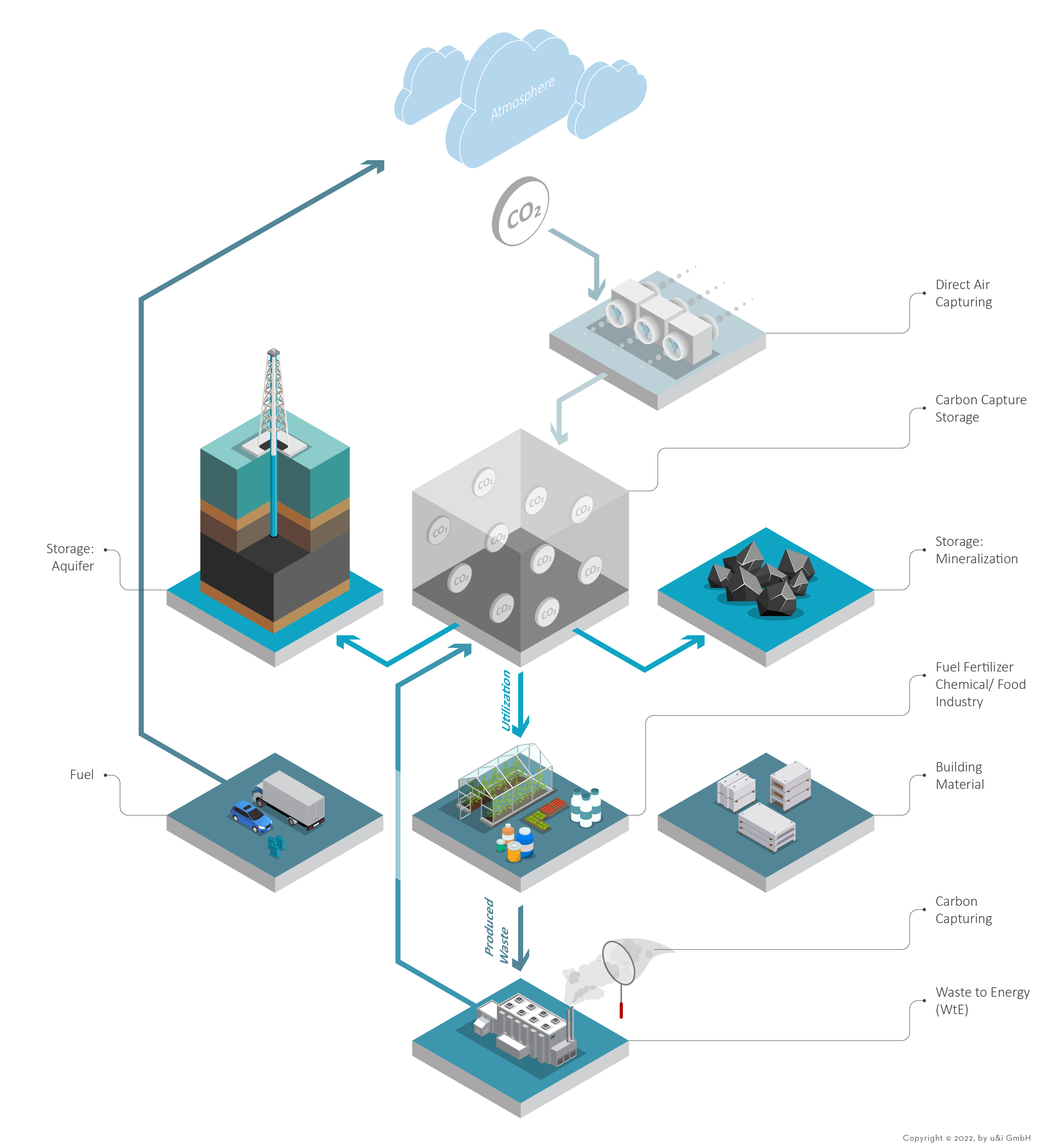

Carbon dioxide (CO2) acts as a greenhouse gas in the earth's atmosphere and therefore contributes to global warming in the long term. In the current discussion about reducing these greenhouse gas emissions in order to achieve the goals of the Paris Agreement, carbon capture (CC) is considered to be of great importance. In future, CO2 will no longer be seen as a waste product but as a raw material in a wide range of applications and will become part of the circular economy in order to reduce global CO2 emissions.

Overall, the topic of carbon dioxide/CO2 is in a state of flux. Markets are changing and new ones are emerging - as are technologies and process combinations. Against this background, the current lines of action and possibilities are presented in simplified form below and finally the terms most frequently used in this context are summarized and explained.

When capturing CO2, a distinction can be made between direct capture from the atmosphere using direct air capture (DAC) and post-combustion capture (PCC) of CO2 from the exhaust gas of power plants and other facilities.

In DAC technology, there are various processes such as amine scrubbing, absorption by sodium hydroxide or membrane separation to reduce the CO2 concentration in the atmosphere by means of so-called geoengineering and slow down climate change mitigation. However, all of these methods have the disadvantage of very high capture costs. Therefore, when implementing CC to reduce greenhouse gases, direct capture at power plants tends to be considered. In order to reduce CO2 emissions at power plants, various processes have been developed, which are roughly divided into three areas.

|

Pre-Combustion |

|

Post-Combustion |

|

The capture of CO2 before the combustion process in the pre-combustion process is mainly used in gas and coal-fired power plants. In this process, carbon monoxide is converted to CO2 by water vapor through a water-gas shift reaction and removed from the process before combustion. |

|

The post-combustion process describes the extension of flue gas cleaning in a power plant by means of CO2 separation in the flue gas that escapes. Similar adsorbents and absorbents are used here as in the DAC process. |

The main difference between DAC and point source capture is the fact that the DAC process reduces the CO2 content of the atmosphere. With point source capture, CO2 neutrality of the plant is usually achieved through the integration of CC. However, this depends on the further handling of the CO2 and can be considered in more detail in the context of a CO2 balance, the creation of corporate carbon footprints or the creation of climate gas balances.

One possibility is storage (CCS - carbon capture and storage), for example through sequestration in pure form in depleted gas deposits or special rock strata, in order to remove some of the CO2 emissions from the cycle. However, this is only the case for biogenic fuels, while the carbon balance for fossil CO2 remains unchanged with the help of CC. However, as storage is heavily dependent on geographical conditions and the possibility of re-emission cannot be ruled out at the present time, research is also being carried out into the mineralization of CO2. This process is analogous to natural rock formation and involves a lower risk. In addition to storage, the focus is also on the use of CO2 (CCU - carbon capture and utilization). New products can be created in various processes by incorporating carbon dioxide. For example, the supply of CO2 and Hydrogen in a Power to X plant offers the possibility of producing hydrocarbons from renewable sources. Further applications can be found in the chemical industry for the production of synthetic compounds, in urea production, in greenhouses or as a basis for building materials.

In this context, so-called Bioconversion Processes can be mentioned as a third and indirect way of using CO2. These can be used to technically convert organic waste into stable carbon compounds (e.g. using pyrolysis or HTC). This biochar / biochar is more difficult for microorganisms to access, so that further natural degradation to CO2 is interrupted. By introducing the charcoal into the soil, CO2 is removed from the atmosphere in the long term, while at the same time plant growth and the binding of CO2 by means of photosynthesis can be promoted. These processes are often referred to as BCR (Biochar Carbon Removal).

In addition to BCR, another widely used approach is BECCS (Bioenergy Carbon Capture and Storage). This aims to capture and store (CCS) or utilize (CCU) the CO2 from bioenergy applications.

The following overview provides a summary of the most common terms and abbreviations:

BCR - Biochar Carbon Removal

BECCS - Bioenergy with Carbon Capture and Storage

CC - Carbon Capture

CCF - Corporate Carbon Footprint

CCS - Carbon Capture and Storage

Das mit diesen Verfahren abgeschiedene CO₂ kann entweder als Gas behälterlos in unterirdische Speicher gepresst werden, wie zum Beispiel alte Erdgas- oder Erdöllagerstätten. Dies wird als geologische Speicherung bezeichnet. Alternativ kann das CO₂ auch mineralisiert werden, indem es chemisch in feste Mineralien umgewandelt wird. Diese mineralisierten Produkte können dann in alten Bergwerken oder anderen geeigneten geologischen Formationen gelagert werden.

Beide Methoden dienen dazu, das abgeschiedene CO₂ sicher und dauerhaft zu speichern und so zur Reduzierung der Treibhausgasemissionen beizutragen.

CCU - Carbon Capture and utilization

In contrast to CCS, the CO₂ is not permanently removed from the cycle in CCU, but is released back into the atmosphere for later use. CCU processes therefore have no direct climate protection effect, as the CO₂ is ultimately released again. However, a certain climate-protecting effect can be achieved by substituting primary raw materials with the captured CO₂.

CCU technology has the potential to reduce the use of fossil resources and thus indirectly contribute to reducing greenhouse gas emissions.

CSRD - Corporate Sustainability Reporting Directive

DAC - Direct Air Capture

In DAC, air is taken from the atmosphere and passed through these technologies to capture the CO₂. The result is pure CO₂ and low-CO₂ atmospheric air.

ESG - Environment, Social, Governance

ESRS - European Sustainability Reporting Standards

European Green Deal

GHG - Protokoll - Greenhouse Gas Protocol

GWP - Global Warming Potential

PCC - Post-Combustion Capture

The technologies used in PCC are similar to those of Direct Air Capture (DAC), such as amine scrubbing or absorption by sodium hydroxide. Operating a PCC plant can significantly reduce the CO₂ emissions of a power plant.

However, it should be noted that the operation of a PCC plant can increase the fuel requirements of a power plant.

PCF - Product Carbon Footprint

The PCF usually takes into account various greenhouse gases such as carbon dioxide (CO₂), methane (CH₄) and nitrous oxide (N₂O), which are emitted throughout the life cycle of a product. This includes the extraction of raw materials, production, transportation, use and disposal of the product.

By calculating the PCF, companies can identify their emissions and take targeted measures to reduce their2 footprint. Consumers can use the PCF to choose more environmentally friendly products and reduce their own ecological footprint.

SDG - Sustainable Development Goals

We are happy to support you with the integration of a process into your planned plant as well as with the expansion of your existing plant.

Thanks to our expertise in the planning of incineration plants with flue gas cleaning, we can support you in all planning phases, from the initial idea and approval through to implementation and commissioning.

Are you considering whether it is worth expanding your plant? We would be happy to draw up a CO2 Balance sheet for your current system and support you with the assessment.

Please feel free to contact us.

Copyright © 2026 - umwelttechnik & ingenieure GmbH - All rights reserved.