Hydrogen

Hydrogen will steadily gain importance as an energy carrier in the future. With the help of hydrogen, it is possible to store renewable energies and to produce existing basic chemical substances (e.g., methane, methanol, ammonia) sustainably. As a result, today's energy sources, such as crude oil or natural gas, are being replaced increasingly.

Hydrogen is obtained through various forms of energy and production processes. For better distinguishing of the types of hydrogen, different colours are assigned to the various production processes. The hydrogen does not change its colour; it remains transparent. The designation emphasises how environmentally friendly (green hydrogen) or harmful (grey hydrogen) the respective process is. The following diagram (Figure 1) provides a brief overview of the presently most important colours (processes).

Figure 1: Overview of the colours of hydrogen

Currently, the production of environmentally harmful grey hydrogen is still very high, but this is to be replaced by green hydrogen by 2050. Today, approx. 90 % of the hydrogen demand is produced from fossil fuels, the rest is produced from electricity and water. For this purpose, water is split into its elementary components (oxygen and hydrogen) with the help of electrical energy in an electrolyser.

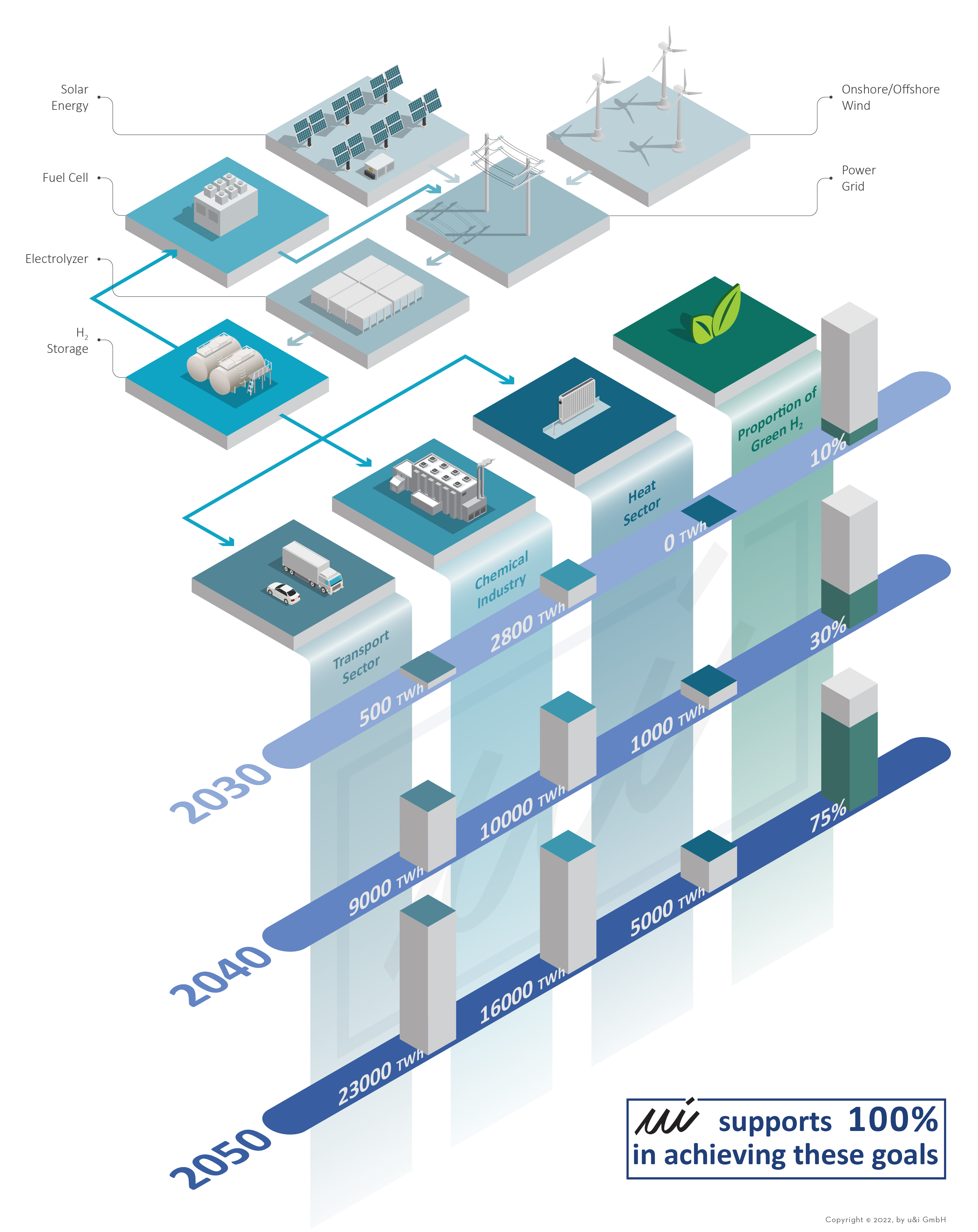

The process of producing hydrogen by "splitting" water is called electrolysis. By using green electricity, e.g., from solar and wind plants, the hydrogen becomes CO2-neutral. The German government is already providing substantial funding for the expansion of electrolysers and the hydrogen infrastructure. Due to the ever-increasing CO2 taxes, the production of green hydrogen will be further pushed. By 2050, this should account for 75% of the hydrogen market. In addition, annual global demand for hydrogen is expected to increase almost twenty-fold to over 40,000 TWh by 2050.

Hydrogen can be used in the transport sector, in industry and in the heating sector as an energy storage medium. This can also be seen in the diagram (Figure 2).

Compared to battery storage, hydrogen can store energy for much longer and with fewer losses. Currently, hydrogen is the best option for flexibly storing large amounts of energy. This will play a major role in the transition to 100 % renewable energy. Through the use of fuel cells, the stored hydrogen can be converted back into electricity in a very flexible way, which means that the fluctuations in the electricity grid can be balanced out quickly and dynamically.

The graph shows how the demand for hydrogen is increasing globally in the transport, industry, and heating sectors. In 2050, it is expected that about 23,000 TWh will be needed for transport. The largest consumers here will be heavy road transport, public transport, rail transport, air transport and the shipping sector. The advantage compared to conventional batteries is the high energy density, i.e., more energy can be stored per weight, thus increasing the range of vehicles.

The industry will have a demand of approx. 16,000 TWh. In order to minimise the current demand for crude oil the steel industry and the production of power fuels through power-to-X plants will play a major role. The steel industry can use hydrogen instead of blast furnaces to produce CO2-neutral steel via direct reduction processes.

The use of a fuel cell not only produces electricity but also heat, which can be used in the form of waste heat. A total of 5,000 TWh of energy will be needed in the heating sector in the future.

There are many opportunities to reduce global CO2 emissions by integrating (green) hydrogen into the energy economy. In our opinion, particular plants in the waste management sector have great potential to convert regeneratively generated electricity into green hydrogen and, among other things:

- integrate the heat produced into existing infrastructure systems at the sites (self-supply) or

- decoupling the heat generated via local or district heating networks,

- converting logistics systems to hydrogen (self-sufficiency),

- increase the methane yields of existing plants by means of in-situ methanisation,

- to close internal material and energy cycles by using the resulting oxygen (e.g., use of oxygen for aeration of wastewater treatment, aerobisation, desulphurisation, introduction into combustion processes).

Of course, we support you - both in the integration of electrolysers (incl. the necessary peripherals) in existing plants and in the construction of new plants on greenfield sites. We support you in all planning phases and concerns, from the initial idea to the approval planning, to the realisation and commissioning.

Figure 2: Hydrogen production and projected demand until 2050

1 Cf. Neugebauer, Reimund: Hydrogen Technologies, 1st ed. 2022, Springer Berlin Heidelberg; Springer Vieweg, p.207-211

2 Cf. Kuhlmann, Andreas: Hydrogen - Enabling the Integrated Energy Transition, 08.10.2021: Hydrogen Online Conference: German Energy Agency (dena)

Please do not hesitate to contact us.