Mono-incineration of Sewage Sludge

Sewage sludge is a waste stream produced in sewage treatment plants and is biologically very active. It consists mainly of the fractions water, organic matter, micro-organisms (e.g. pathogenic germs) and organic and inorganic pollutants (e.g. heavy metals, PAH, microplastics, drug residues) (1). Due to the extremely heterogeneous nature of these materials and the growing pollutant loads, safe storage, safe transport and comprehensive treatment are becoming increasingly important. In many emerging and developing countries, sewage sludge is rarely handled appropriately. Due to a lack of infrastructure, illegal dumping is often observed, which has a significant negative impact on human health and the environment, leading to economic losses.

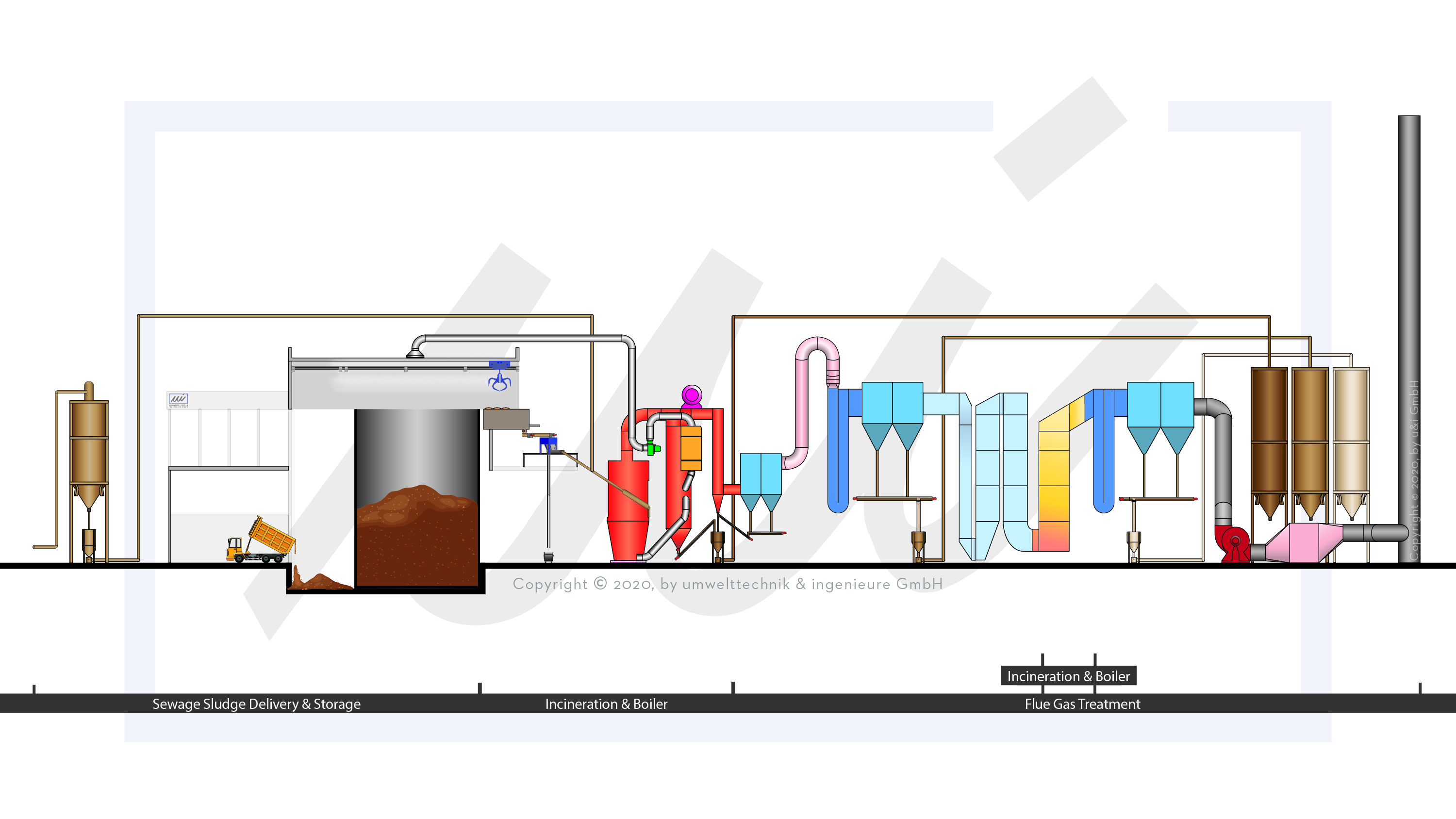

The agricultural and thermal use of sewage sludge has become established in Europe. Nevertheless, more unconventional, alternative processes for material or energy recovery are also used, such as hydrothermal carbonisation (HTC), pyrolysis or gasification. Due to increasing contamination, growing hygienic concerns and the resulting adjustments in jurisdiction (AbfKlärV and DüV/DüMV), there is an increasing tendency to refrain from agricultural sewage sludge recycling. In addition to the future prohibition of agricultural use, the new jurisdiction also stipulates nutrient recycling. One way to continue to meet these requirements is the thermal utilization of sewage sludge with subsequent phosphorus recycling from the sewage sludge ashes produced. A possible process structure of a sewage sludge incineration is shown in the following figure.

The exemplary process design of a sewage sludge incineration plant.

Raw sludge usually consists of 96 - 98 % water and 2 - 4 % solids. Depending on the effectiveness of the dewatering process, an increase in the dry substance content to 20 - 30 % is possible. At the same time, the proportion of organic dry matter is 40 - 75 % and the ash content 25 - 60 % (1.3).

The high water and ash content of the dewatered sewage sludge results in a low calorific value of 0 - 2.5 MJ/kg dry matter. A minimum calorific value of approx. 4 - 4.5 MJ/kg dry matter is required for independent combustion in a fluidized bed furnace (4). Additional drying of the sewage sludge before feeding it into the incinerator is essential.

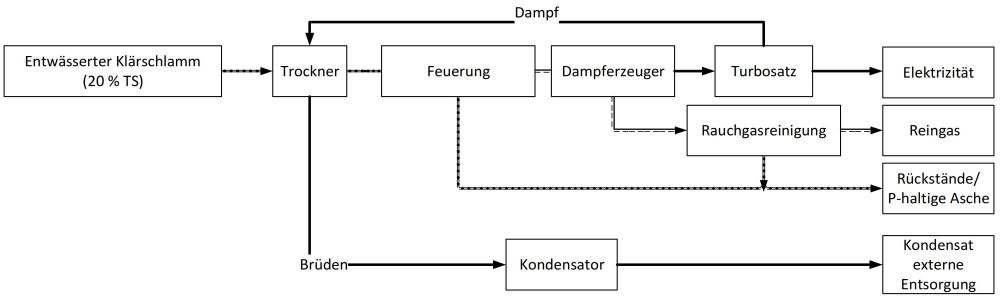

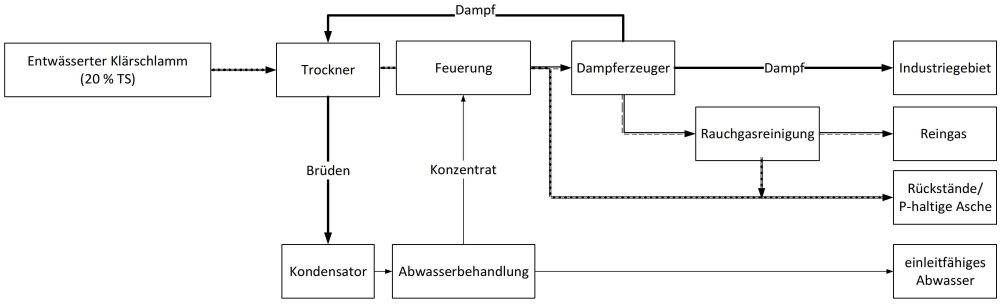

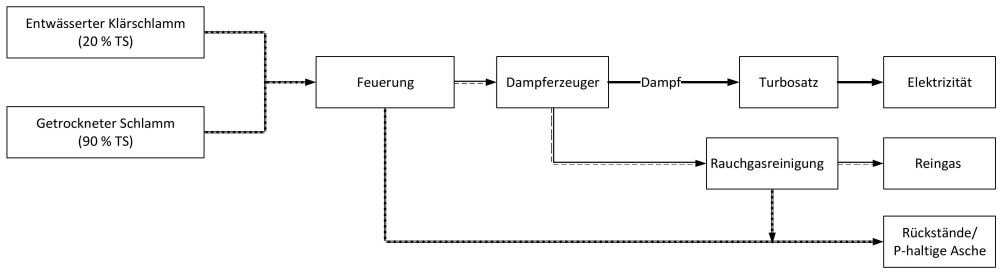

The facts described show that no two sewage sludges are the same, which means that the formulation of general requirements for sewage sludge recycling can only be simplified. The plant concepts illustrated below show different process variants to comply with sewage sludge recycling:

Concept 1

Concept 2

Concept 3

We would be pleased to support you in developing and implementing your individual solution in the field of sewage sludge recycling. The same applies to the integration of comprehensive nutrient recycling in order to comply with all legal requirements in the future.

Please feel free to contact us.