Business Segments - Circular Economy

Hydrothermal Carbonization (HTC)

Since Hydrothermal Carbonization (HTC) is particularly suitable for the treatment of wet/damp organic waste, this process will be discussed in more detail here.

HTC is a conversion process for modifying moist organic waste (e.g. fermentation residue or sewage sludge) in such a way that the products are coal-like compared to the starting material and, among other things, have improved dewatering properties. For this purpose, the starting material is converted under hydrothermal conditions (in the presence of water at temperatures around 200 °C in a gas-tight reactor).

The first investigations into this procedure were carried out about 100 years ago by the Nobel Prize winner Friedrich Bergius in Hanover. The aim of the investigations was to imitate and exploit the natural formation of coal by technical means. Further work followed, but without much resonance and success. It was not until the growing importance of sustainable technologies in the context of climate and resource protection that the hydrothermal process received new attention under the keyword "HTC" - not least thanks to umwelttechnik und ingenieure GmbH in Hanover.

Since its "rediscovery" in 2006, the technology has developed very rapidly and various new business models have been opened up. This can be measured, among other things, by the fact that numerous research projects have been successfully carried out and various industrial plants have been developed and put into operation. At the moment, there are various plant manufacturers on the market who offer various process engineering concepts. As long-term experience is still lacking, it is difficult to compare and evaluate these concepts, especially against the background of changing legal requirements.

The following is, therefore, a summary of the main features and potential of HTC.

For the HTC process, the water-wetted starting material is heated in a closed reactor to a temperature around 200 °C, so that a saturation vapour pressure is formed. The properties of the organic material change under these reaction conditions. Changes can be seen in the increasingly darker colour of the dried products (see Figure 1), whereby the carbon content and calorific value of the products increase simultaneously.

Figure 1: Range of HTC products to be obtained: Untreated biomass (left) up to highly carbonised biomass (right) differ significantly in colour and chemical/physical properties.

A special feature of the HTC is that the desired product quality can be significantly adjusted via the reaction temperature and the reaction time (usually less than 5 h). The process is also exothermic overall, i.e. part of the energy stored in the biomass is released and thus contributes to the fact that less energy has to be used to maintain the reaction temperature of about 200 °C.

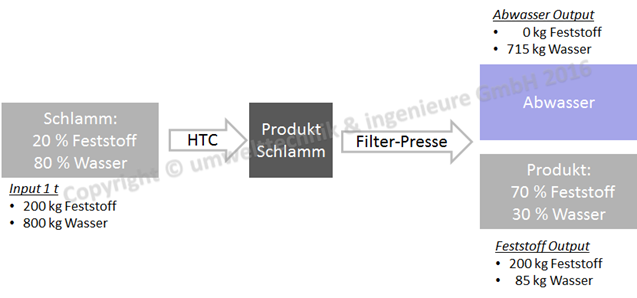

After hydrothermal treatment, the product sludge produced is further recycled, whereby the mechanical dewatering properties are significantly improved (see Figure 2). Thus, unstabilized sewage sludge can be dewatered to a maximum of 30% solids (and 70% water) before HTC, but to a solids content of up to 70% (and 30% water) after HTC. The produced coal-like target product can be used as a fuel, among other things, because the reduced water content in the solids significantly increases the potential for energetic use.

Figure 2: Example of the application of hydrothermal carbonization for the treatment of sludges: Depending on the starting material and process conditions, the mass of sludge can be reduced by 2/3.

Due to the numerous dissolved organic components, the wastewater can be fermented, so that on the one hand methane can be produced as an energy source and on the other hand the chemical oxygen demand (COD) of the wastewater is significantly reduced. Phosphorus recovery is also possible, especially for the treatment of sewage sludge.

Since the "rediscovery" of HTC, we have been dealing with the topic, on which we now have more than 900 scientific papers, reports and publications from the HTC subject area. In addition to our own practical experience (dissertation on the kinetics and thermodynamics of HTC) in process engineering implementation, these form an extensive database. Combined with the knowledge of more than 26 years of experience in environmental technology and engineering we offer as an independent engineering office to advise you on all aspects of HTC and to develop individual concepts for you.

Our core competencies in this context include

- Performance audits

- Project reviews

- Preparation of expert opinions

- Due diligence/valuation.

Please feel free to contact us.